-

Wind turbines

Thousands of our shrink discs ensure each year that wind turbines throughout the world are able to safely and reliably generate electricity from wind. STÜWE shrink discs type HSD connect the rotor shaft in the main drive train with the gearbox hollow shaft. Gearbox flange shafts are fastened to the rotor shaft using flange couplings type FKHA. Locking units type AS join the coupling and the brake disc on the high-speed side of the gearbox shaft. Locking units type IS and type AS are used in direct drives between the generator shaft and generator rotor.

-

Thousands of our shrink discs ensure each year that wind turbines throughout the world are able to safely and reliably generate electricity from wind. STÜWE shrink discs type HSD connect the rotor shaft in the main drive train with the gearbox hollow shaft. Gearbox flange shafts are fastened to the rotor shaft using flange couplings type FKHA. Locking units type AS join the coupling and the brake disc on the high-speed side of the gearbox shaft. Locking units type IS and type AS are used in direct drives between the generator shaft and generator rotor.

-

Cushing equipment

Our frictional shaft-hub connections ensure that your machinery is driven reliably and maintenance-free by the gear unit or geared motors. Thus, shrink discs type HSD are used to connect a gear unit with a roller, roller presses or crushing plants. Shrink discs type HSD are also suited for the fastening of a rolling element to a roller.

-

Cushing equipment

Our frictional shaft-hub connections ensure that your machinery is driven reliably and maintenance-free by the gear unit or geared motors. Thus, shrink discs type HSD are used to connect a gear unit with a roller, roller presses or crushing plants. Shrink discs type HSD are also suited for the fastening of a rolling element to a roller.

-

Driveline technology

Our frictional connections ensure that your gearboxes, couplings, belt and chain drives or other driveline components safely drive the machine shaft. Thus, gearboxes are fastened to shafts using shrink discs type HSD. External locking units type AS are used to connect couplings or pulleys with a shaft. Gearwheels are joined backlash-free with a shaft using internal locking units type IS or shrink discs type SDG.

-

Driveline technology

Our frictional connections ensure that your gearboxes, couplings, belt and chain drives or other driveline components safely drive the machine shaft. Thus, gearboxes are fastened to shafts using shrink discs type HSD. External locking units type AS are used to connect couplings or pulleys with a shaft. Gearwheels are joined backlash-free with a shaft using internal locking units type IS or shrink discs type SDG.

-

Shipbuilding

High dynamic loads and life-long durability: the high demands in ship propulsion are reliably overcome by Shaft Couplings and Flange Couplings from STÜWE.

-

Shipbuilding

High dynamic loads and life-long durability: the high demands in ship propulsion are reliably overcome by Shaft Couplings and Flange Couplings from STÜWE.

-

Convoyer systems

Our frictional connections ensure that your conveyor and transportation belts are safely driven by the gear unit or geared motors. Complete swinging gear units are connected with a belt drive shaft using our flange couplings type FKH / FKHA. Shrink discs type HSD fasten geared motors to a conveyor belt shaft. Internal locking units type IS or also external locking units type AS can fasten your pulleys to a shaft.

-

Convoyer systems

Our frictional connections ensure that your conveyor and transportation belts are safely driven by the gear unit or geared motors. Complete swinging gear units are connected with a belt drive shaft using our flange couplings type FKH / FKHA. Shrink discs type HSD fasten geared motors to a conveyor belt shaft. Internal locking units type IS or also external locking units type AS can fasten your pulleys to a shaft.

-

Steel and rolling mill plants

Steel and rolling mill plants contain highly modern, automated equipment. A common factor in all manufacturing processes is a high demand on reliability. Various different products from STÜWE are therefore used in this area.

-

Steel and rolling mill plants

Steel and rolling mill plants contain highly modern, automated equipment. A common factor in all manufacturing processes is a high demand on reliability. Various different products from STÜWE are therefore used in this area.

-

Mixing and processing equipment

Stirring and mixing are important process steps in such as chemical equipment and the foodstuffs industry. The STÜWE shrink disc type HSD provides a simple mechanical external tensioning of an agitator shaft and gear (engine). STÜWE provides stainless steel, galvanised and nickel-plated shrink discs for corrosive environments.

-

Mixing and processing equipment

Stirring and mixing are important process steps in such as chemical equipment and the foodstuffs industry. The STÜWE shrink disc type HSD provides a simple mechanical external tensioning of an agitator shaft and gear (engine). STÜWE provides stainless steel, galvanised and nickel-plated shrink discs for corrosive environments.

-

Measurement and testing equipment

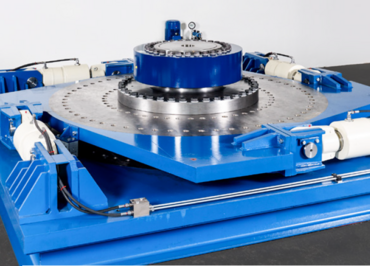

The construction of a test bed demands a great deal of flexibility both in tests parallel to series production for quality assurance purposes and in the individual testing of prototypes. The high positional accuracy in particular, both in the direction of turn and in an axial direction, provides a great deal of flexibility.

-

Measurement and testing equipment

The construction of a test bed demands a great deal of flexibility both in tests parallel to series production for quality assurance purposes and in the individual testing of prototypes. The high positional accuracy in particular, both in the direction of turn and in an axial direction, provides a great deal of flexibility.